INJECTION MOLDING MACHINE

Injection molding machine is a mechanical equipment used to inject molten plastic into a mold, which then forms the desired product during the cooling and solidification process. It efficiently saves costs and enhances production efficiency. It is one of the most commonly used mechanical equipment in the modern plastic processing industry, widely applied in the manufacturing of various plastic products.

MATERIAL PROCESSING

Plastic pellet processing refers to the pre-treatment and processing of raw plastic pellets to ensure high-quality plastic products during the injection molding process. This process includes steps such as storage, drying, mixing, and screening of plastic pellets.

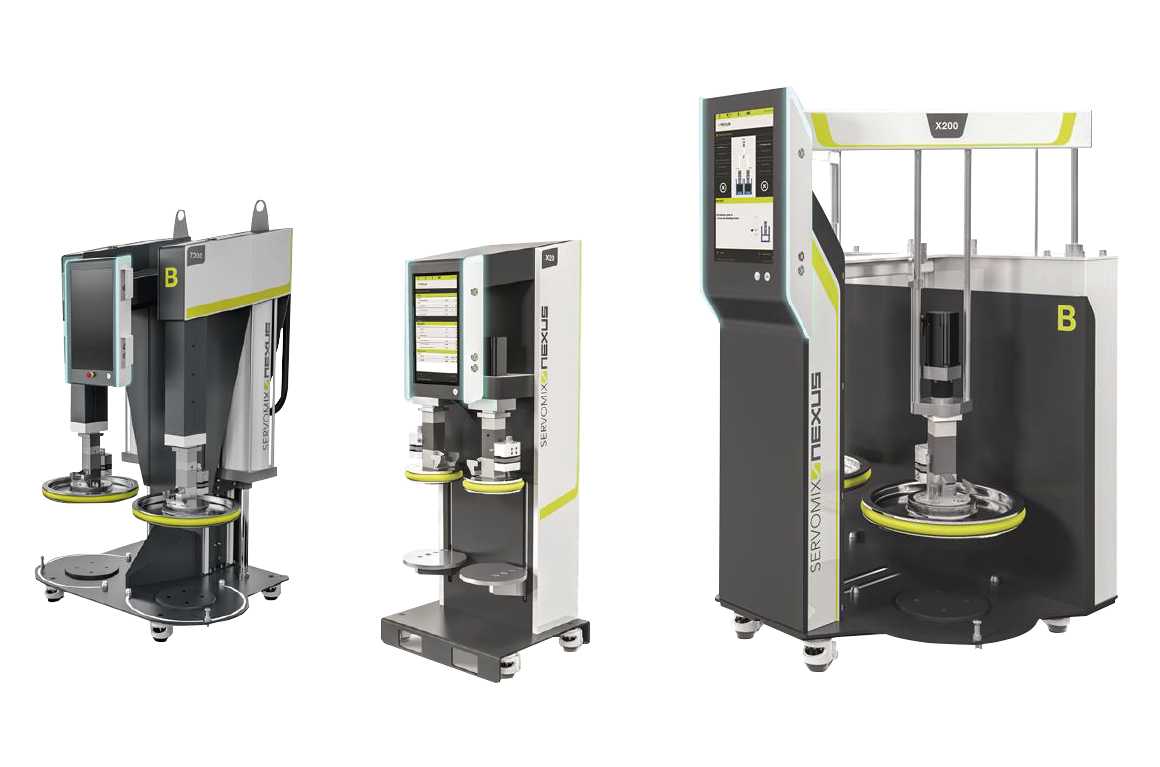

MOLD MONITORING

Mold temperature controller, also known as mold temperature regulator, is a device used to control the temperature of injection molds. It maintains a stable temperature for the mold during the injection molding process by controlling the temperature and flow of cooling or heating fluid. Its functions include controlling mold temperature, stabilizing injection molding parameters, speeding up production cycles, and extending the life of the mold.

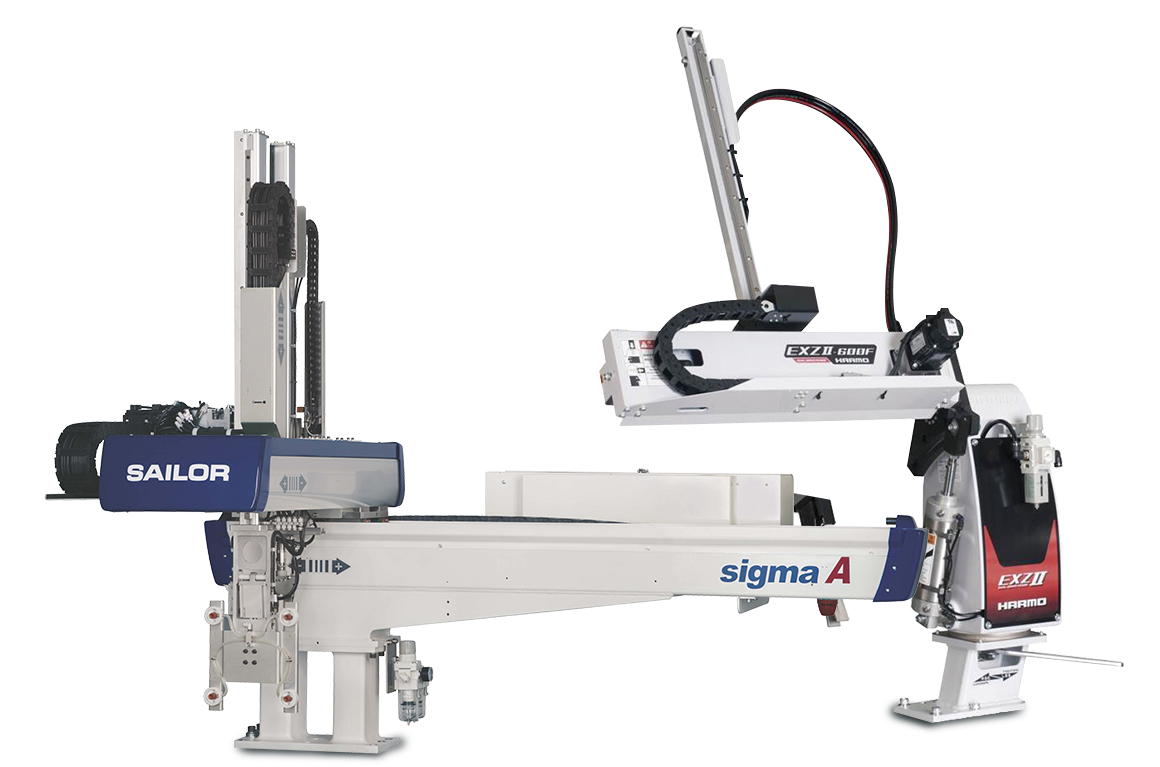

AUTOMATION

Automated technology and equipment are employed in the injection molding process to enhance production efficiency, reduce labor costs, and improve manufacturing consistency. Through the application of automation, the injection molding industry can achieve highly automated production lines, allowing for unmanned or minimally supervised operations from raw material processing to final product packaging.