CONAIR

Central Conveying system

Central Conveying

system

Gravimetric Batch

Blenders

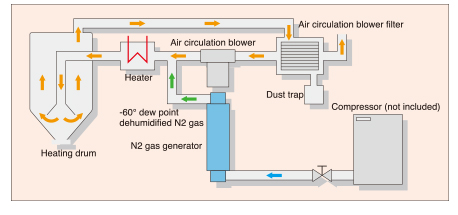

Dehumidifier Dryer System

SlimLine

CONAIR stands as a global leader in the plastics processing peripheral equipment industry, boasting the largest customer base worldwide. The company is dedicated to assisting its customers in boosting productivity, improving production efficiency, and resolving challenges encountered in the manufacturing process. With unparalleled planning capabilities and professional expertise, CONAIR is the sole manufacturer in the industry that offers a comprehensive range of over 450 types of plastic processing peripheral equipment, setting it apart in both production and marketing.

Product type

- Raw material conveying equipment

- Dehumidification and dryer system

- Metering and mixing systems

- Ice-water/mold temperature controller

- Scrap recycling

- Automatic extraction robot

- Cutters and extrusion equipment

- Energy Smart drying and energy saving system

Cutters

Cutters