Sodick

Vertical Injection Molding Machine

TR75VRE(Vertical Injection Molding Machine) Vertical Swing Type

TR75VRE(Vertical Injection Molding Machine) Vertical Swing Type

TR20VRE / TR40VRE / TR75VRE / TR100VRE / TR150VRE

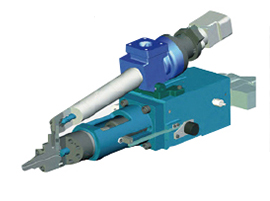

Sodick, guided by the sincere principle of 'providing guidance for the manufacturing of customers' items,' listens to various subtle requirements from customers, challenges and overcomes various difficulties, and collaborates with customers to solve problems. In addressing challenges, Sodick adopts a unique approach to develop solutions for items that have not been seen before in the world. Leveraging excellent technology and experience, Sodick's V-LINE separates the processes of plasticization and injection, ensuring a stable state of plasticization and precise filling, which is its major feature. These innovations have now become the source of competitiveness for Sodick's products.

Product type

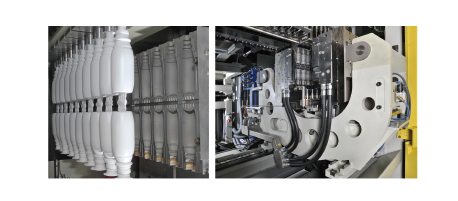

- Insert injection molding

- Thermo-curing injection molding

- BMC injection molding

- LIM liquid injection molding

- Pulling injection molding

- Rubber injection molding

- FBT vacuum impregnator vacuum impregnator

- CIM ceramic injection molding

- Mold assembly injection molding

- Two-color injection molding

- Dewaxing molding

- MIM metal powder injection molding

V-LINE®way

V-LINE®way

High speed leak detector

High speed leak detector