HARMO

Linear guide

Recommended instructions

for Swing type

- Using servo motors for the Z-axis and Y-axis reduces retrieval time by 35%.

- Retrieve teaching data from the internal mold storage. No need to adjust the stroke when changing molds, ensuring high efficiency.

- Plastic chains are used for the front and rear axes to protect pipes and wiring. Smooth operation and a clean appearance.

- Linear guides are used for the vertical and horizontal axes, achieving fast and stable motion without any shaking.

- Below the linear guide, equipped with lubricant to prevent leakage. (Standard configuration for front and rear axes, optional for vertical and horizontal axes)

- EXZII series EXZII-600(F) / EXZII-800(F)

Recommended instructions

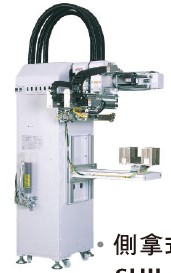

for Side-entry type

- Reduces retrieval time by over 30%.

- High rigidity, reduced deflection.

- Accuracy improved by 50% compared to the old model.

- Shortening the distance between the fixed side and the gate clamp can reduce the response time by 18ms (0.018s).

- Centralized oil supply device is provided as a standard feature, reducing maintenance time.

- SHII series SHII-700H / 700GH

Side-entry type SHII-700

EXZ Pendant Controller

HRS-140-SHII Controller

HLC-AT50BHS

HLC-AT50BHS