ALBRECHT

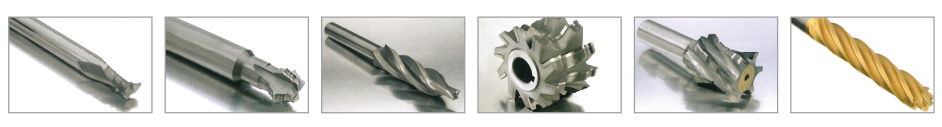

APC High-precision and High-clamping force Milling Chuck

High-precision and High-clamping force Milling Chuck

High-precision and High-clamping force Milling ChuckFounded in 1908 in Stuttgart, Germany, ALBRECHT is a pioneer in powerful milling chuck heads. Committed to maintaining precision in tool holding, they employ pressure gauges and custom fixtures to inspect all components at every stage of the production process. ALBRECHT's high-precision, powerful milling chuck heads currently demonstrate the best performance in the world in terms of cutting speed, tool life, and safety. If you're looking to improve chip removal, extend tool life, and enhance processing reliability, ALBRECHT is the optimal choice.

Advantages

- The world's only vertical milling chuck head with a 1:16 turbo.

- Highly rigid body design.

- High-strength, securely locked turbo capable of withstanding dry and heavy cutting processes at temperatures up to 110°C.

- Unique shock absorption and suppression force.

- Quick-change drill chuck handles.

- Customizable tool handles.

- High-precision quality, high clamping force, superior cutting performance—significantly boosts cutting processing efficiency.

NSK / Slim5 HSK / SK

NSK / Slim5 HSK / SK MAS-BT / MICRO / POLYGON

MAS-BT / MICRO / POLYGON

Wave Nozzle

Wave Nozzle